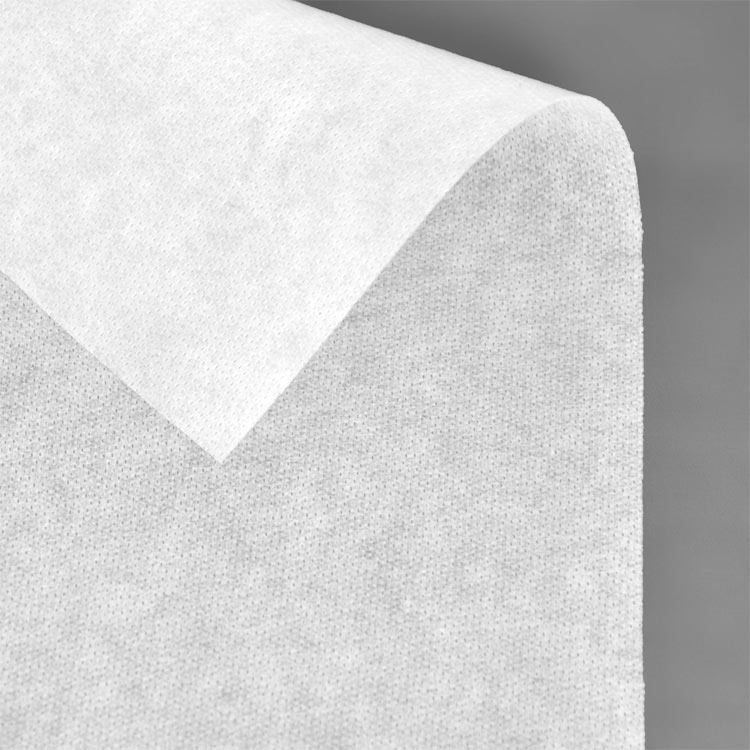

Non Woven Fusible Interlining

7 INR/Meter

Product Details:

- Product Type Linings

- Material Polyester

- Lining Type Fusible

- Fabric Type Other

- Pattern Plain

- Length 1016 Millimeter (mm)

- Width 2032 Millimeter (mm)

- Click to View more

X

Non Woven Fusible Interlining Price And Quantity

- 7 INR/Meter

- 5000 Meter

Non Woven Fusible Interlining Product Specifications

- 1016 Millimeter (mm)

- Linings

- Polyester

- 2032 Millimeter (mm)

- Other

- Mix

- Plain

- Fusible

Non Woven Fusible Interlining Trade Information

- Cash Against Delivery (CAD), Cash Advance (CA)

- 5000 Meter Per Day

- 3 Days

- Yes

- Free samples are available

- 80 to 100 meters per roll

- All India

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Non Woven Interlinings' category

Works Address:

Near Cement Godown, Kanganwal,

Focal Point Ind Area-C, Ludhiana (Punjab)

Phone: +91-161- 2512222

Fax: +91-161-2512223

Contact Person: Mr. Manish Jhanji

Mobile: 08068090068